Filter the results

Showing 1–6 of 161 results

Bi-directional knife gate valve

“The gate valve model EB from Orbinox is a bi-directional wafer type knife gate valve.

The knife gate valve was designed for waste water treatment applications.

The design of the housing and seat ensures blockage-free shut-off when using suspended solids in many areas.”

Globe valves in 2- and 3-way design

The Burocco soft or metal seated 3-way control valves are specially designed for control operations in medium and low-capacity plants.

The Burocco control valves have a 3-way body with screwed seats and a switching or mixing function. The valve cone type V-Port is guided into the seats from above and below.

Seal type: Soft (class VI) or metal (class IV – V)

Characteristic: Linear

DIN und ANSI Sicherheitsventil für den Niederdruckbereich

Die Type 1216B ist ein geflanschtes Sicherheitsventil für den Niederdruckbereich in DIN und ANSI. Flexibilität in der Ausführung.

Diese Ausführung ist auch in der Kombination Flansch-am-Eintritt und Gewinde-am-Austritt verfügbar jeweils in DIN und ANSI als auch gemischt.

Durch lagernde Gehäuse und vieler verschiedener Innengarnituren steht einer schnellen Lieferung nichts im Wege. Weiters können die Vetile auch noch mit anderen Zusatzoptionen aufgerüstet werden.

Verschiedene Zulassungen stellen sicher, dass diese Armaturen auch in sehr anspruchsvollen Industrien zum Einsatz kommen.

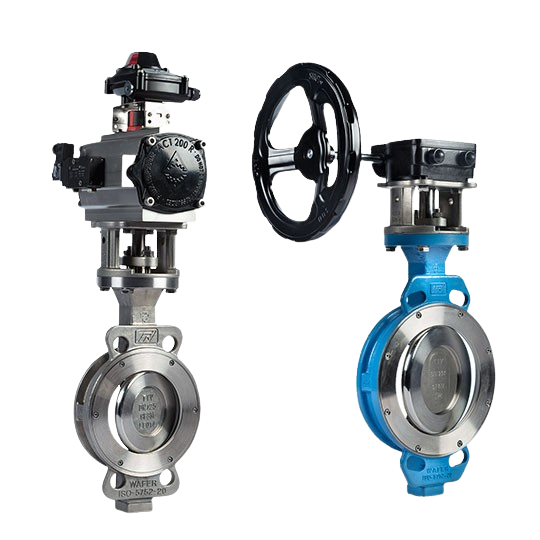

Double eccentric, high performance butterfly valve Colossus

Die Doppelexzentrische Hochleistungs-Absperrklappe bietet eine dichte Absperrlösung für die anspruchsvollsten Anwendungen.

Weitere Varianten im Programm: Konzentrische, doppelt exzentrische und dreifach exzentrische Ausführung.

Uni-directional knife gate valve

“The knife gate valve from Orbinox type ET is a uni-directional knife gate valve for industrial applications according to MSS-SP-81 and TAPPI TIS 405-8 standards.

The design of the housing and seat ensures blockage-free shut-off when using suspended solids in many industrial sectors.”

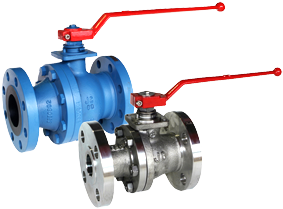

DIN flanged ball valve, short pattern, floating

“The JC Valves flanged ball valve type 516 / 540 is a floating ball valve according to DIN with a short DIN face to face length.

The standard version of the ball valve includes a anti-blow out stem, an antistatic device, a pressure balancing cavity hole and a “”live loaded”” packing.

A large selection of materials makes the soft seated, floating DIN flanged ball valve flexible to use.

With a wide range of approvals (Fire Safe, Fugitive Emission, ATEX, TRCU, CRN, SIL 3, and many others), it can be used in virtually all industries. “