We want to make sure that

only the success of our customers explodes.

That’s why we have all products with the corresponding safety certificates in our range.

Where highly explosive media are processed, such as in the petroleum and chemical industries, the safe operation of plants is vitally important.

High safety requirements for a wide variety of components are the decisive criterion, while at the same time production efficiency.

Whether explosion safety, failure probability or emission values, we offer the appropriate valve with the corresponding certificates, such as ATEX, AD 2000, SIL or TA Luft (Technical Instructions on Air Quality Control).

Our Topseller valves for the petrochemical and chemical industries

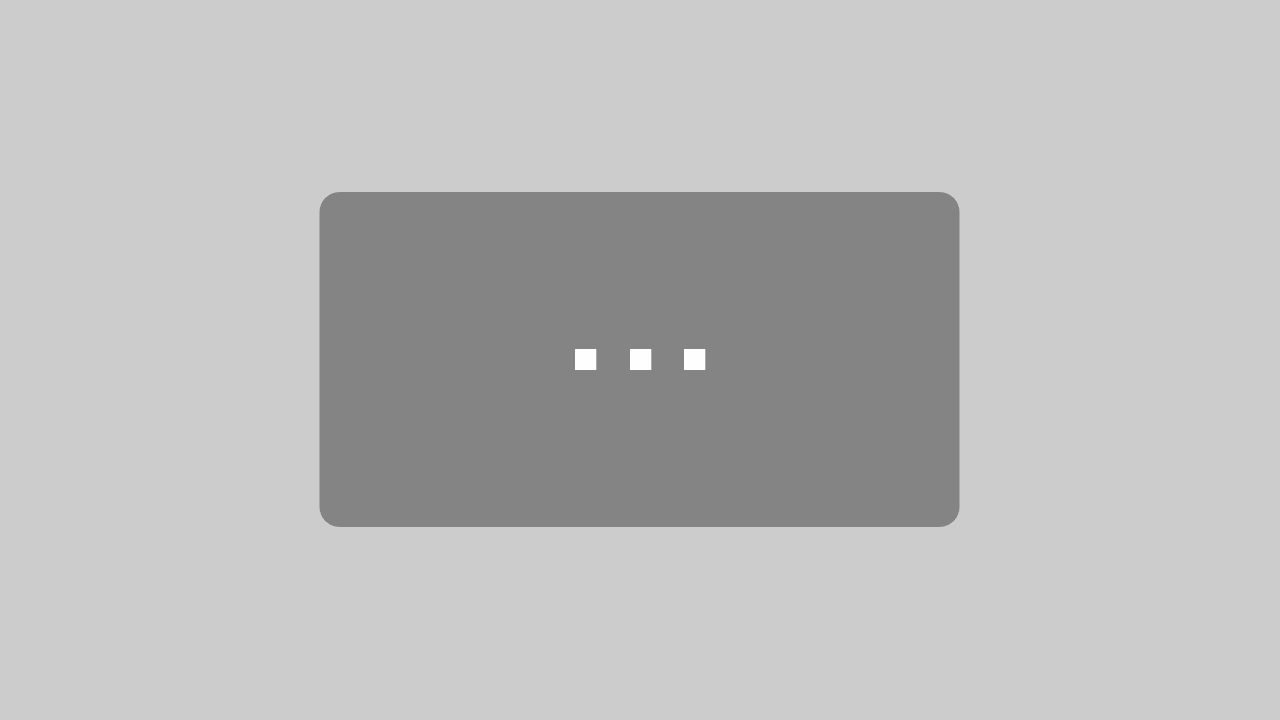

Metal seated, DIN flanged ball valve, long/short pattern, floating

“The JC Valves ball valve type 3516 / 3540 / 3316 / 3340 is a floating ball valve with a metal seal. It can be designed in both a long or short DIN face to face length.

The standard version of the ball valve includes a anti-blow out stem, an antistatic device, a pressure balancing cavity hole and a “”live loaded”” packing.

A large selection of materials makes the metal seated, floating DIN flanged ball valve flexible to use. With a wide range of approvals (Fire Safe, Fugitive Emission, ATEX, TRCU, CRN, SIL 3, and many others), it can be used in virtually all industries. “

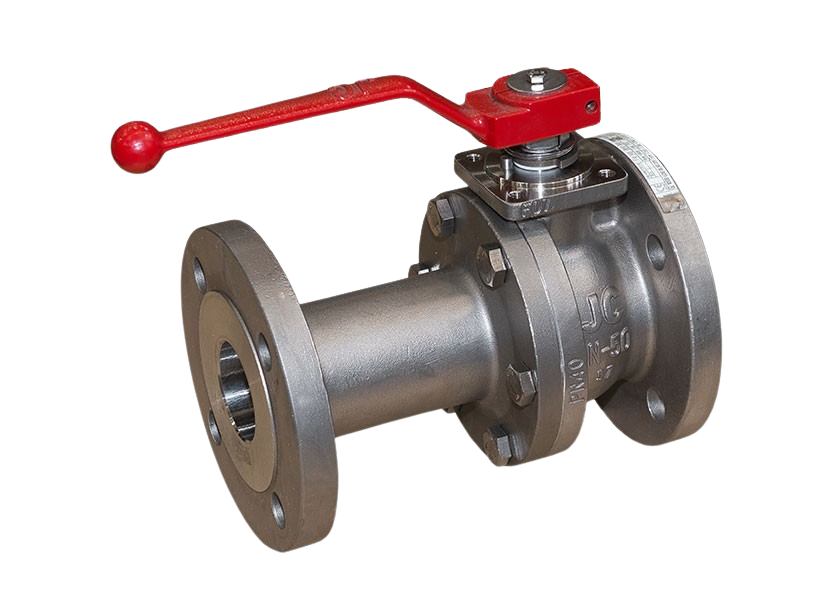

DIN safety relief valve

Flanged safety valve for the low and high pressure range according to DIN. For a very huge range of applications.

The Tosaca safety valve DIN 1400 is available in different materials and designs and can therefore cover an extreme range of applications.

Because of a big stock of different kind of valve bodys and many different trims, nothing stands in the way of quick deliveries. The valves can also be equipped with other additional options.

Various approvals ensure that these valves are also used in very demanding industries.

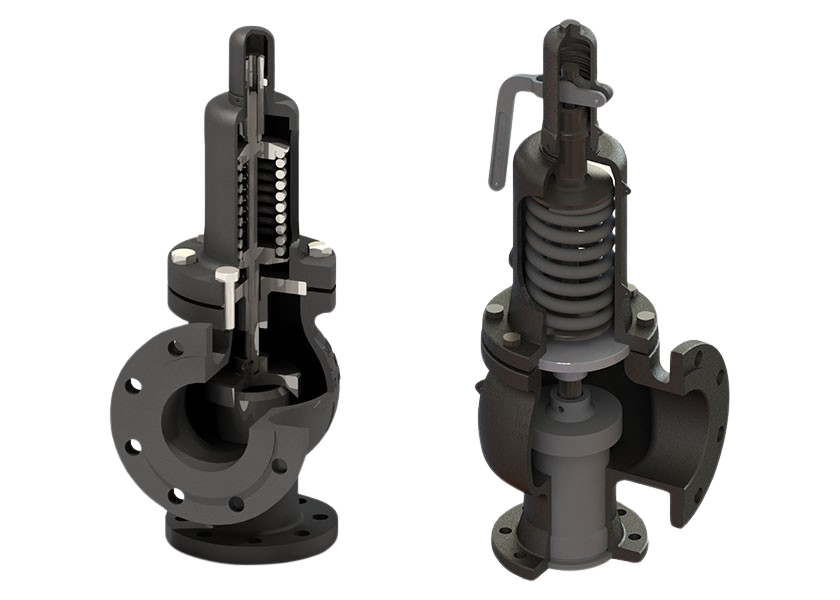

Metal seated DIN gate valve

“Metal seated RT Valvole gate valves in cast design are used when minimal pressure drop and/or a bi-directional ON/OFF operation is required.

All standard gate valves have a “”full bore”” because the wedge is completely retracted in the open position. This ensures minimal pressure drop.

Design:

* The housing material is made of cast steel.

* The valves have a bolted or pressure seal bonnet (for higher pressure) to achieve minimal turbulence and flow restrictions.

* Fixed, flexible or split wedge types are available.”

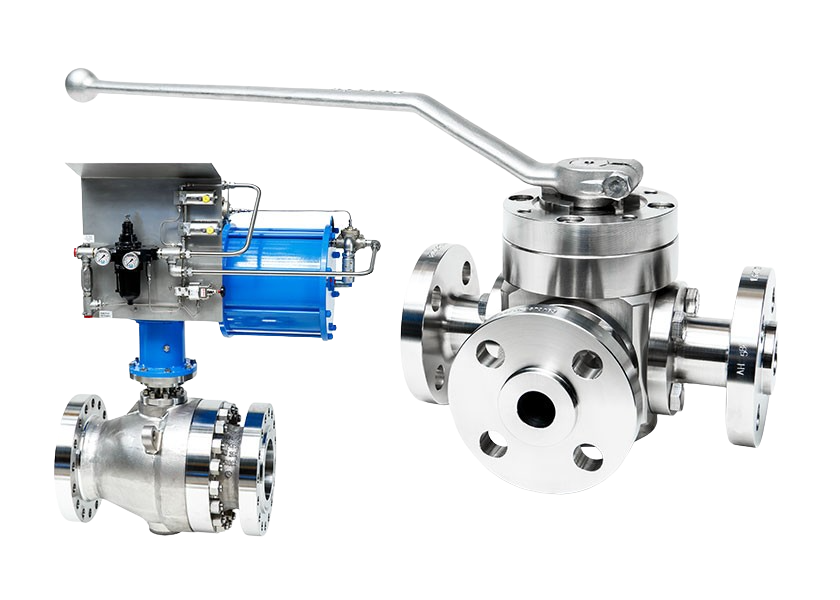

Two and multi-way ball valve for demanding applications

“The Kitz multi-way ball valves are used to distribute or reroute a wide variety of media.

There are basically two different types: one type that routes all connections on one level and another type with a connection that is rotated downwards at an angle of 90°. This is intended to make planning and installation much easier.

The ball valves are available in a soft and metal seated version depending on the application.”

Valves selection for petrochemical & chemical industries

You can

rest assured.

In addition to explosion safety, chemical media also place special demands on chemical resistance. Valves lined with PTFE or ceramic protect against particularly aggressive chemical media. Special materials, such as Duplex, Superduplex or Hastelloy©, withstand the greatest chemical attacks.

In the petrochemical industry in particular, hot heated media place particular demands on the proper functioning of plants on a sustainable basis. Our cavity free valves prevent the valves from stucking so that the system runs continuously without any problems.

Of course, our product portfolio also offers valves for all other requirements, such as high or low temperature. With highly viscous media, not only the high temperature is a criterion, but the butterfly valves have to grip harder to close reliably. We have corresponding products available in our range for this and for all gaseous media, for example with a PET, PE or PU coating.

Find the right fitting quickly and easily.

Our product finder will help you find the valves you are looking for. For individual advice or inf the selection or the standard model does not meet your requirements, please contact us directly Nothing

remains hidden.

Media used especially in the petrochemical industry, such as diesel, benzene or kerosene, are very expensive to produce. During a product changeover, for example in tank farms, valves should be completely emptied and ensure that all media remain where they belong, namely in the process. Here too, we have the right solution to transport this media without any losses and without mixing them.

For special tasks we have niche suppliers in our network who specialise in the chemical and petroleum sectors.

Butterfly valve versus gate valve

Gate valves are tried and tested and good,

but are they good enough?

Have you ever thought about why you use classic gate valves or ball valves for certain steam, gas, low or high temperature applications? At Flowtec, we have scrutinised their use and evaluated whether it is possible to solve this in a different and better way: Yes, you can!

The use of our Quadax® four offset eccentric butterfly valve is an innovative solution that not only withstands extreme requirements. It is much more compact, smaller at a lower weight. At the same time, the Quadax® four offset eccentric butterfly valve offers a high tightness and is also easier to automate.

Ready to strike out on a different path?

A valve solution

that will help you take off safely

An intelligent and efficient refuelling system requires an equally efficient and safe valve solution. We were able to deliver this at one of the most state-of-the-art airports in the German-speaking region with underground refuelling.

The kerosene is pumped through underground lines from a nearby tank farm directly to the aircraft holding bays. The aircraft are refuelled by airfield tanker vehicles without their own tank (dispenser or hydrant truck) through a refuelling pipeline in an underground pipe system.

Absolute safety in the form of 100% tightness has been ensured by a double block and bleed valve. Automatic emptying of the cavity ensures that no aircraft fuel is wasted.