Our winning formula. For cost efficiency and planning certainty.

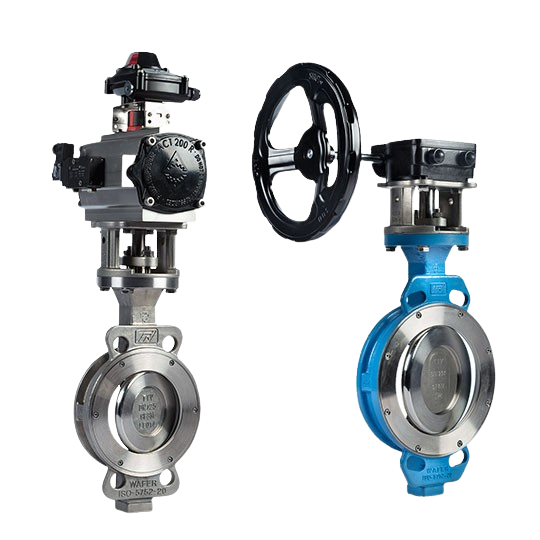

The scope of paper applications is as diverse as the requirements placed on the production plants. In addition to a wide range of valves, customers also search valves with a large operating range providing flexible use.

Avoid downtimes and waste!

To achieve the product quality required in stock preparation, we rely on control and butterfly valves that regulate the compliance with the surface weights, offering the highest precision. We also know which valve is the right one for our customers in the area of pulp dewatering application, so as to avoid fibre bundles and therefore quality defects.

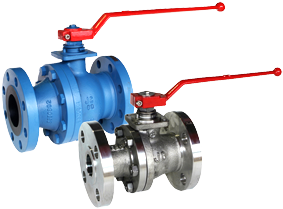

Economical and robust!

For wastepaper applications, design adjustments in reject handling ensure perfect functionality. Customers search wear-resistant models in special paper production, amongst others: Ceramic valves prolong the service life and cost-effective products ensure economic efficiency.