Additional information

| Marken | Somas |

|---|---|

| Funktion | Control valves, On-off valves |

| Industrie | Petroleum, chemical |

| Anwendung | Chemical resistance |

| Nenndruck | ANSI, 150, PN, 10, 16, 25 |

| Betriebstemperatur | Standard temperature |

| Marken | Somas |

|---|---|

| Funktion | Control valves, On-off valves |

| Industrie | Petroleum, chemical |

| Anwendung | Chemical resistance |

| Nenndruck | ANSI, 150, PN, 10, 16, 25 |

| Betriebstemperatur | Standard temperature |

“The Emreson resilient seated butterfly valve is a centric butterfly valve with a split shaft (up to DN300), rounded polished disc edge, centring bores on the valve housing and an extended valve neck allows for pipe insulation.

The type GRW is designed as a wafer type valve and the GRL as a flanged type valve according to EN558 series 20, with a spheroidal cast iron housing and a disc in 1.4408 steel. “

“Somas valves type MTV, MTVG and MTVL are on/off valves and control valves that have been specially developed for oil and gas applications and are designed to control over a wide temperature range.

They are normally supplied with a metal seat.

They are all triple eccentric valves and due to the unique design of the valve disc, a solid stainless steel seat can be used. This solid seat is resistant to high flow velocities and temperatures. This allows us to achieve high functional reliability even in difficult applications.

The MTV valve can be supplied as a wafer type or lug type valve.

The valve type MTVG is a wafer valve with 4 guide bores.”

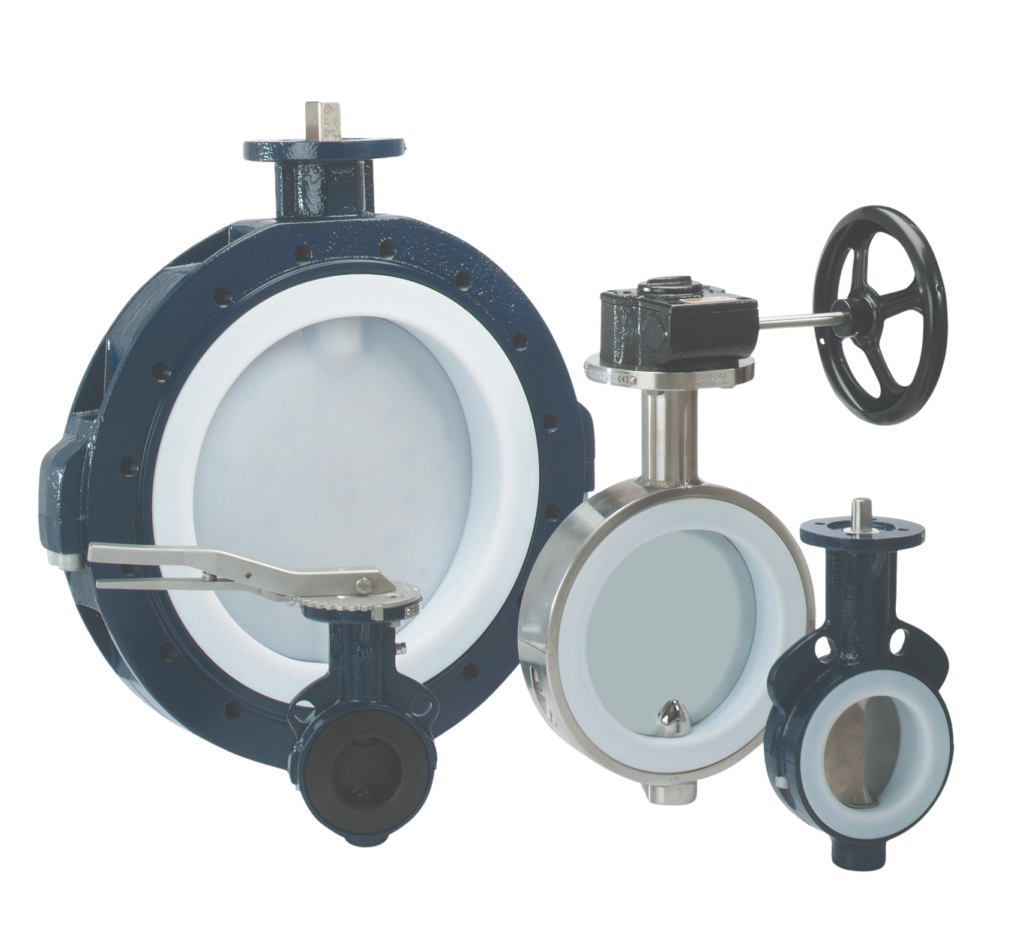

The ChemValve-Schmid butterfly valve CST is the world’s leading modular PTFE lined butterfly valve.

The PTFE lined valve is produced to the highest quality standards for the safe handling of aggressive media. It is designed for the use with highly chemical media and is therefore used in almost all industries.

Spherical structural elements reduce friction and therefore increase the service life.

“The Somas metal seated butterfly / shut-off and control valve type VSS is suitable for controlling and shutting off liquids, steam and gases over a wide temperature range.

The triple eccentric design allows the use of a solid stainless steel seat due to the special contour of the disc. The disc geometry and the shape of the seat provide excellent tightness.

The seat is resistant to high flow velocities and ensures good tightness, even under difficult operating conditions. The seat, which is available in different materials, can be replaced.

The VSS valve was developed as a wafer valve and can also be supplied as a lug type valve (with threaded bores).”

You are currently viewing a placeholder content from Facebook. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Instagram. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from X. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information