Filter the results

Showing 7–12 of 15 results

Dual plate check valve

The ChemValve Schmid dual plate check valve has an eccentric disc and a wafer design.

The flow-friendly design reduces the pressure loss in the system and therefore the energy requirements of the plant.

Another advantage of this valve is that no gland is required due to the design and so it is impossible for the medium to escape.

The dual plate check valve is used in all industrial processes involving liquids, gases or steam.

Metal seated DIN swing check valves

“RT gate valves valvole in cast design are used to prevent backflow in pipe systems. Due to their fully open design, this results in minimal pressure drop.

Design:

* The housing material is made of cast steel. The valves have a bolted or pressure seal bonnet (for higher pressure).

* The valve disc is made with forged material. On request, the disc can be supplied with an overlay of Stellite or other materials.

* The disc hinge joint is designed in such a way to achieve a

perfect tightness, which means a self-positioning disc system. “

Metal-to-metal seat wafer style tilting disc check valve

“The Orbinox metal seated check valve type RM is a robust tilting disc check valve with an oblique seating angle. It is used in all industries, but mainly in the pulp and paper, water treatment and food sectors.

In addition to the short length, it is characterised by a low pressure drop and opening pressure. Another advantage is the reduced pressure surges caused by the quick closing action (oblique seating).

An optional spring accelerates the closing action. “

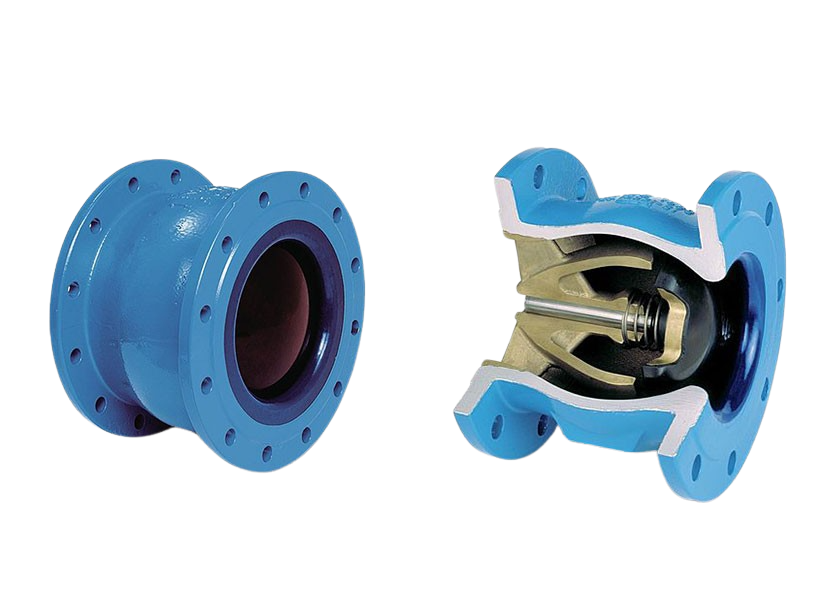

Non slam nozzle check valve

ERHARD nozzle check valves are designed for universal use and are particularly economical check valves for untreated and potable water as well as purified waste water due to their design.

Special features include the ultra-low pressure loss due to optimised flow cross-sections, a flow-efficient valve disc and valve stem gasket, as well as optimum hydraulic behaviour with short closing travel to minimise pressure surges.

Nozzle check valve streamLiner

Piston check and piston closing check valve, forged, metal seated

Wakmet piston check valves made of forged steel prevent the backflow of medium into the pipe. The check valve can also be used as a shut-off valve to open and stop the flow.

Depending on the model, the temperature ranges extend up to 530°C or 670°C (up to ≤ 200°C for PTFE).

Wakmet metal seated piston check valves are mainly used in the energy sector as well as in the pulp and paper industry. Depending on the type, they are suitable for media such as water, steam, non-aggressive and non-toxic media as well as some also for gas, fuel and sea water.