Filter the results

Showing 1–6 of 32 results

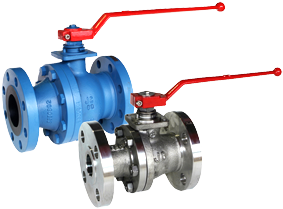

DIN flanged ball valve, short pattern, floating

“The JC Valves flanged ball valve type 516 / 540 is a floating ball valve according to DIN with a short DIN face to face length.

The standard version of the ball valve includes a anti-blow out stem, an antistatic device, a pressure balancing cavity hole and a “”live loaded”” packing.

A large selection of materials makes the soft seated, floating DIN flanged ball valve flexible to use.

With a wide range of approvals (Fire Safe, Fugitive Emission, ATEX, TRCU, CRN, SIL 3, and many others), it can be used in virtually all industries. “

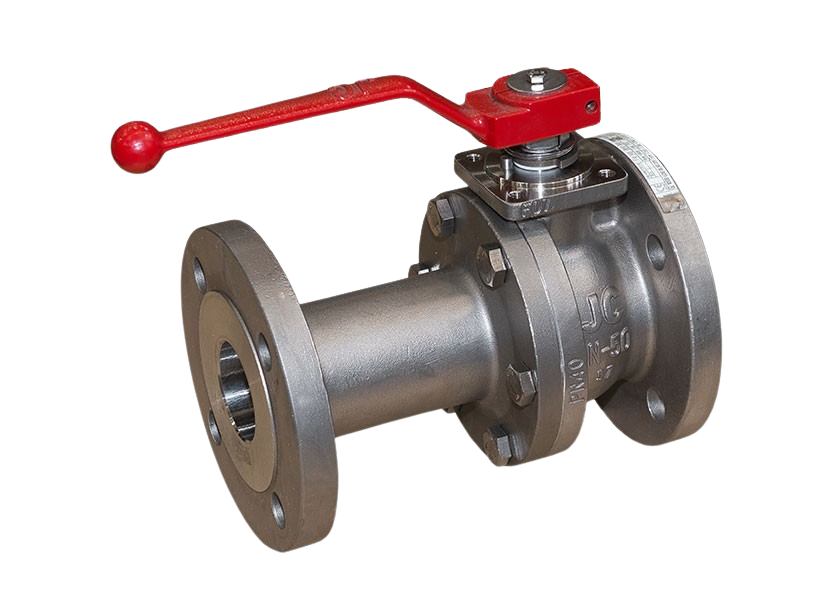

Soft seated, no dead space, fully welded ball valve

“Soft seated, fully welded, minimized cafity flanged ball valve with various approvals.

Due to its design, the fully welded ball valve can also be supplied as a bottom outlet valve.

The connection ends can be designed to suit the customer’s requirements. In addition, many other design options can be selected. “

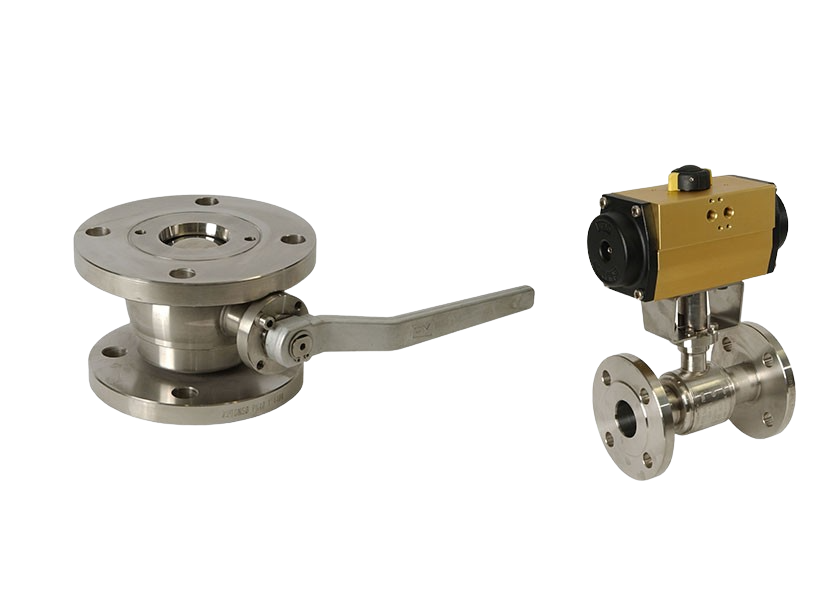

3-piece ball valves

The ICP Valves 3-piece ball valves have a 3-piece nody and are made of stainless steel, in a floating version with a full bore valve design.

Connections:

– KH 140: Thread according to DIN 259/2999 (GAS)

– KH 141: Thread according to ASME B1.20.1 (NPT)

– KH 142: Socket weld ends according to ASME B16.11 & DIN 3239 part 2

– KH 143: Butt weld ends according to ASME B16.25 & DIN 3239 part 1

Marking: CE – PED

PN63 (up to 2”) / PN25 (2½“-4“)