Filter the results

Showing 67–72 of 161 results

Bottom valve

“The Somas bottom outlet valve KVBW / KVBF is a ball segment valve that can be mounted directly on the bottom of tanks. This design minimises the distance between the ball segment and the bottom of the tank.

Design:

Type KVBW: Wafer design

Type KVBF: Flanged design.”

Butterfly valve damper

The throttle valves RD and RA are designed as a wafer type valve with a centric valve disc and are suitable for operating temperatures up to 800°C, depending on the choice of material.

For flanges according to DIN EN 1092-1 or ASME B16.5 / ASME B16.47. Lengths according to the company standard.

Connecting flange for actuators to DIN EN ISO 5211.

Testing according to DIN EN 12266.

Versions:

RD without seat (leakage approx. 1% of surface equivalent),

RA with metal travel stop ring (leakage approx. 0.5% of surface equivalent),

RA with seal ring (leakage approx. 0.3% of surface equivalent),

RA with metal travel stop ring with seal ring (leakage approx. 0.1% of surface equivalent)

Butterfly valve Hydromat®

Der HYDROMAT® ist eine extrem robuste Absperrklappe mit zentrisch gelagerter Klappenscheibe, die durch bewährte konstruktive Merkmale eine jahrzehntelange Betriebssicherheit gewährleistet und somit Kosten spart, da keine unnötigen Reparaturen anfallen.

Butterfly valve, low temperatur

“The Somas butterfly valve type VSS LT is designed for a wide range of liquids, gases and steam for temperatures down to -196°C (-320°F).

The valve can be designed as a control, on/off or manual valve.

The VSS LT valve can be supplied in a wafer and lugged design.

The valve has a triple eccentric valve design. The unique shape of the disc enables the use of a solid stainless steel seat. The solid seat remains unaffected by high flow velocities and provides good valve function, even in the most difficult applications.”

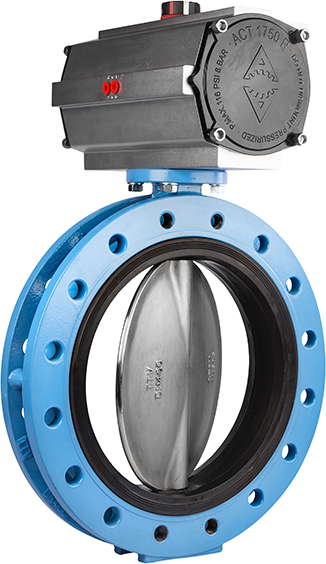

Centric flanged / double flanged butterfly valve

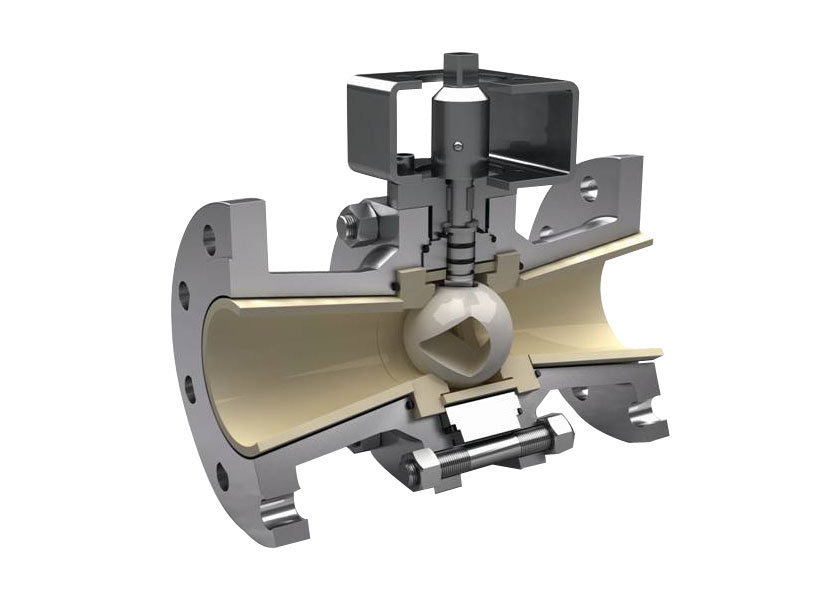

CeraValve ceramic lined ball valve

Cera Valve offers wear and corrosion-resistant ceramic lined ball valves for on/off and control functions.

The use of ceramic-lined valves make sense wherever standard valves reach their limits (abrasion, corrosion, temperature and pressure).

A large selection of variuos ceramic materials allows for solutions for almost all industrial sectors. Special adaptations and special applications are also solved in close cooperation with our customers.